Specialized Solutions for the Industry

Cutting-edge technology to maximize efficiency in hydrocarbon measurement, production, and control

At Grupo SODI, each of our services is backed by advanced infrastructure and specialized technology.

Throughout our journey, we have developed key solutions such as:

- Design and manufacturing of the first explosion-proof equipment nationwide (1985), with 4-20 mA transmitters and digital display, ensuring safety in critical operations.

- Implementation of our patented technology in multiphase flow meters, optimizing the precise measurement of crude oil, gas, and water without physical separation.

- Use of cutting-edge equipment for production monitoring and control, ensuring accurate data and enabling real-time strategic decision-making.

We drive operational efficiency in the energy industry

Our services are designed to optimize processes, reduce risks, and ensure precision in hydrocarbon measurement and production.

Hydrocarbon Measurement with Three-Phase Separators

Advanced solution for the precise separation and measurement of crude oil, water, and gas, optimizing production and ensuring efficient resource management.

- High-volume processing, with a capacity of up to 12,000 BPD and 60 MMPCD.

- Real-time monitoring with advanced telemetry and data analysis.

- Automated system, eliminating manual testing and optimizing flow.

- Certified precision, meeting international standards.

- Adaptability to various well conditions, maximizing hydrocarbon extraction.

- Environmental compliance, reducing emissions and optimizing resources.

Fluid Measurement with Multiphase Equipment

Our patented technology enables the simultaneous quantification of crude oil, gas, and water without physical separation, improving accuracy and reducing analysis time.

- High measurement accuracy, with a maximum uncertainty of 2% in liquids and 3% in gas.

- Real-time inline measurement without interrupting production processes.

- Non-radioactive technology, eliminating environmental risks.

- Data processing with advanced algorithms, ensuring measurement stability.

- Compatible with SCADA systems and advanced analysis software.

- Modular and scalable platforms, adaptable to any field operation.

Sustainable Energy Solutions

Sustainable infrastructure designed for safe and efficient operations, with renewable energy systems that reduce environmental impact.

- 100% autonomous system with zero CO₂ emissions, aligned with sustainable practices.

- Real-time remote monitoring, ensuring operational efficiency and control.

- Hybrid energy systems, combining renewable and conventional sources.

- Optimized energy consumption, reducing costs and emissions.

- Water and energy storage, ensuring field self-sufficiency.

- Compliance with environmental regulations, minimizing ecosystem impact.

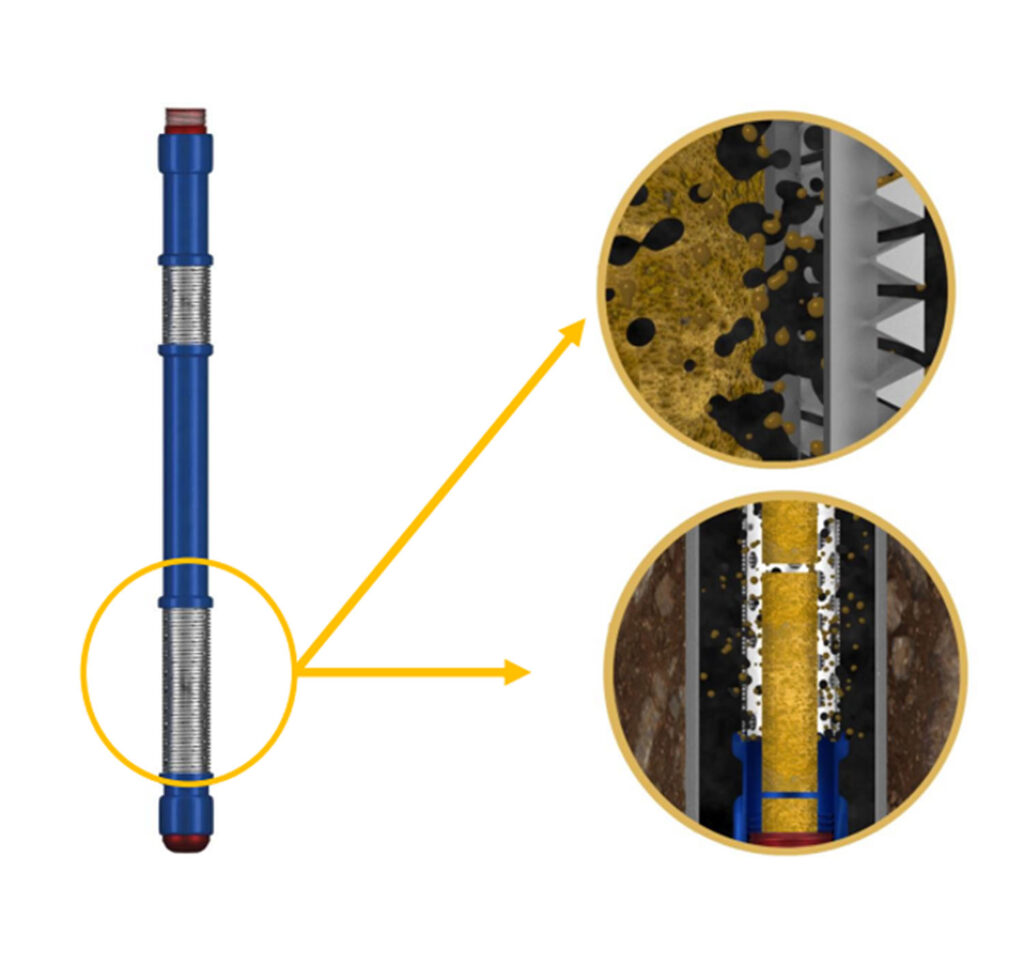

Completion Chemicals

Specialized chemical solution designed to optimize well performance after drilling, using controlled-release technologies and compatibility with artificial lift systems.

- Additive microencapsulation, gradually or directly released depending on well conditions.

- Protection against corrosion, scaling, foaming, and paraffin buildup.

- Application with retrievable tools, compatible with any ALS system.

- Improved operational efficiency and reduced mechanical intervention.

- Precise dosing that extends the production system’s lifespan.

- Technology developed for severe conditions and wells with high chemical complexity.

Hydrocarbon Pumping

Pumping systems designed to adapt to different types of fluids, pressures, and flow rates, ensuring operational continuity and extraction efficiency.

- Positive displacement, centrifugal, and progressive cavity pumps.

- Pumping capacities from 250 to 11,000 BPD and pressures up to 15,000 PSI.

- Applicable for hydrocarbons, drilling fluids, and produced water.

- Equipment adaptable to low-pressure conditions or highly viscous fluids.

- Specialized technical support in design, installation, and field operation.

- Technology optimized to reduce energy consumption.

Sand Control

Advanced protection for production equipment, preventing blockages and premature wear.

- Equipment like ESP Sand Lift, UltraMesh, and Vortex Shield to prevent sand failures.

- Downtime reduction and extended service life in artificial lift systems.

- Filtration technology to minimize solids entry and protect equipment.

Gas Separation

Solutions for efficient gas removal in hydrocarbon production, improving the quality of extracted fluids.

- Packer and packerless separators to remove gas before it reaches the pump.

- Increased production efficiency and system component protection.

- Reduced emissions and fewer premature failures.

Well Stimulation

Solutions to increase mature well productivity and maximize hydrocarbon recovery.

- Reactive and non-reactive solutions, such as synthetic acid, solvents, and diverter systems.

- Controlled fracturing and acidizing techniques.

- Improved permeability and productivity in mature wells.

Artificial Lift Systems (ALS)

Advanced solutions to optimize production in low-flow wells.

- Supervision, operation, and maintenance of pneumatic and mechanical lift systems.

- ABM installation with wireline trucks and pressure testing.

- Valve and equipment calibration for low-pressure wells.

Hydraulic Valve Control System

Advanced control systems to improve operational efficiency and reduce emissions.

- Hydropneumatic system with 0% gas venting, no compressor required.

- Smart control powered by solar energy and remote monitoring.

- High operational efficiency with low cost and minimal emissions.